Redefining efficiency across multiple industries: the transformative impact of advanced magnetic braking systems

In a groundbreaking development, GRW, a leading technology company, is collaborating with a prominent food processing company to equip conveyor systems with magnetic brakes. This collaboration is set to significantly reduce electricity bills and improve safety standards, while driving innovation across various industries.

Magnetic brakes, particularly magnetic powder brakes, are becoming increasingly popular in manufacturing, logistics, and food processing industries. These brakes offer numerous benefits, including precise torque control, smooth tension regulation, and enhanced production quality.

In manufacturing, magnetic powder brakes are extensively used in processes requiring accurate tension control such as printing, packaging, textile manufacturing, film extrusion, steel rolling, and coating lines. Their ability to maintain constant or variable torque ensures materials are handled without damage, improving product quality and operational consistency.

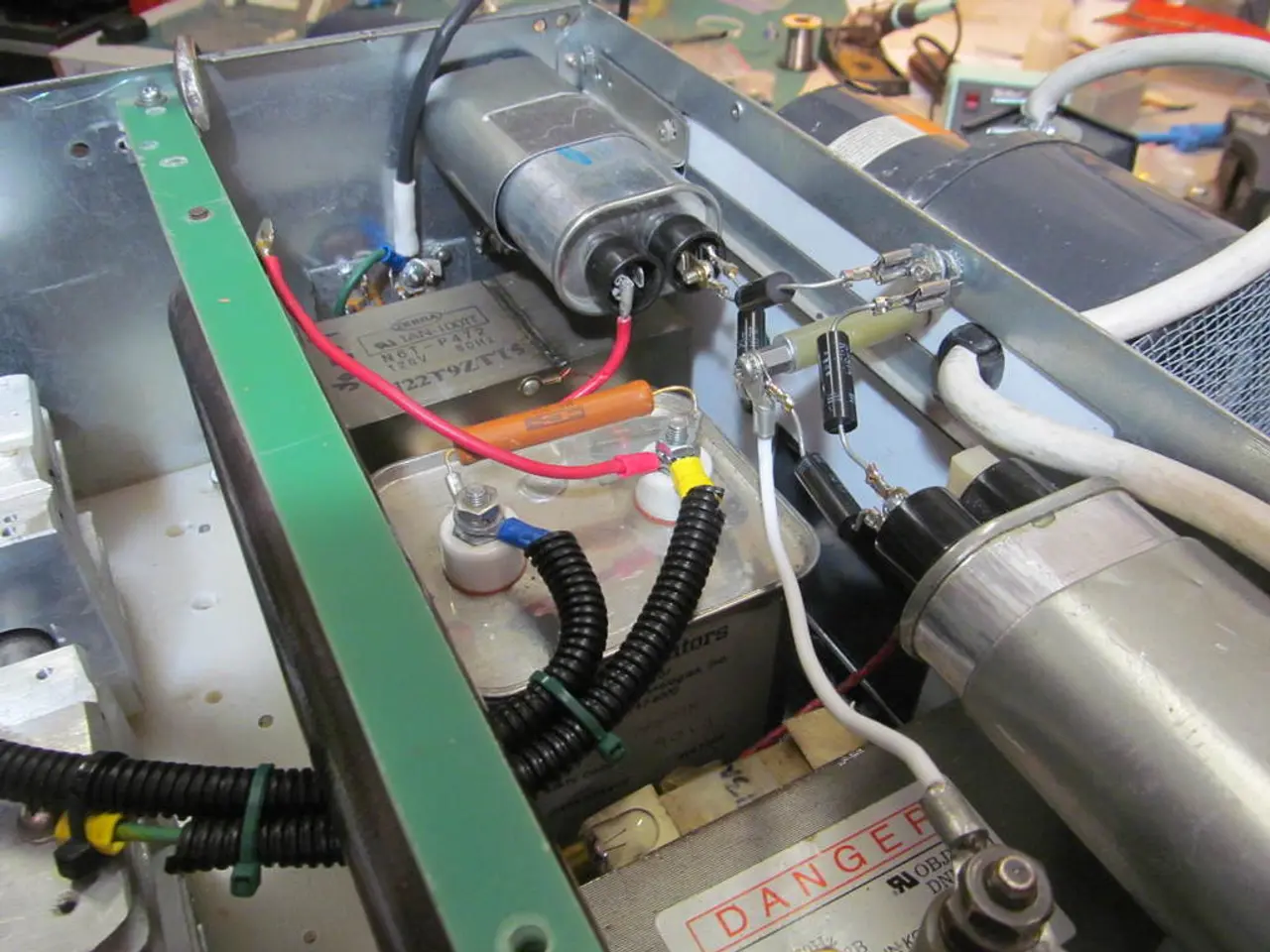

In logistics and material handling, these brakes support conveyors and motor test rigs by regulating torque smoothly and protecting mechanisms from mechanical shocks. Their rapid response time and long operational life make them suitable for precise automated manufacturing setups where braking force needs continuous and adaptive control.

In food processing, the key features of magnetic brakes—reduced friction and contamination risk due to non-contact braking—align well with hygiene and sustainability requirements common to that sector. Their eco-friendly operation helps reduce waste and supports sustainable manufacturing goals.

Magnetic brakes operate using magnetic fields to control and reduce motion. They provide a potent solution for enhancing efficiency, lowering costs, and embracing the future of automation across various industries. The maintenance costs of magnetic brakes are significantly lower compared to traditional systems due to their robust design and extended operational periods without malfunction.

Advanced control systems will allow magnetic brakes to operate with even greater precision and flexibility, monitoring real-time performance and adjusting settings to optimize efficiency. Magnetic brakes equipped with energy-efficient features contribute significantly to the green transition, allowing businesses to reduce energy consumption without sacrificing performance.

The future of magnetic brakes is promising, with advancements set to revolutionize industries around the globe, converging efficiency, precision, and sustainable practices. Research into intelligent magnetic systems that can learn and adapt to varying conditions is pushing the boundaries of magnetic brake technology, signaling a new era in industry automation.

In conclusion, the adoption of magnetic brakes is set to transform operations across various sectors, enhancing operational safety, reducing maintenance costs, providing fine torque adjustment through manual or automatic control modes, shortening downtime, and contributing to greener manufacturing processes. As industrial automation trends continue to evolve, the potential of magnetic brakes to drive innovation and efficiency is undeniable.

In the manufacturing sector, magnetic brakes are extensively utilized in industries such as printing, packaging, textile manufacturing, film extrusion, steel rolling, and coating lines, owing to their ability to maintain constant or variable torque and improve product quality.

In the home-and-garden industry, these brakes' non-contact operation and reduced contamination risk make them suitable for hygiene-conscious applications, aligning well with the sector's sustainability requirements.

Finance and business industries might benefit from the lower maintenance costs and energy-efficient operation of magnetic brakes, leading to cost savings and a reduced carbon footprint.

In the realm of data-and-cloud-computing and technology, advancements in magnetic brake technology, such as intelligent learning systems, could significantly impact automation processes, leading to increased efficiency and precision.